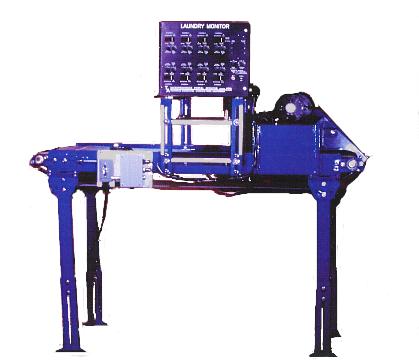

LAUNDRY MONITORING SYSTEM

MODEL # LIM-21GFA

FEATURES:

- FULL DYNAMIC BACKGROUND SUBTRACT

- OUTSTANDING SENSITIVITY TO FISSION

PRODUCTS SPECTRUM

- ADVANCED N OF 8 DESIGN

- 8 CHANNELS OF COUNTING ELECTRONICS

- AUDIO AND VISUAL RADIATION ALARMS

- HIGH BACKGROUND ALARM

- LOSS OF SIGNAL LIGHTS

- FAST FLOW THROUGH OF LAUNDRY

- EASY TO READ ALARM PANEL FOR MOUNTING ON WALL OR PORTAL

|

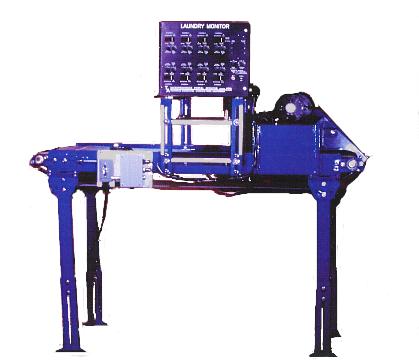

LIM-21GFA

|

APPLICATION: The LIM-21GFA

examines each garment for radioactive contamination. A large

throughput can be attained with a minimum amount of supervision.

DESCRIPTION: The LIM-21GFA

consists of converyer belt with eight detectors and separate

table top, (also rack mountable) electronics. A cabinet to hold electronics

and counting gas bottle is optional. Eight gas flow radiation detectors

and one motion detector, sense contamination on an item of clothing.

The eight radiation detectors are divided into eight separate channels,

one for each detector. This feature makes it easier to locate and

remove contamination, and increases sensitivity by lowering the background

count per channel.

When unoccupied, the LIM-21GFA averages

background radiation over 20 second interval. A first-in-first-out

shift register updates the background data every 0.2 seconds. When

the belt is occupied the electronics compare the background plus 1,

1.4, or 2 times the background standard deviation, to the laundry

radiation count. This comparison is made every 50, 100, or 200 milliseconds

depending upon the setting of the front panel sample time switch.

The level of confidence ( N of 8 ) can be set for each channel

using the eight position switches on the electronics console. Separate

alarms are provided for each channel.

SPECIFICATIONS:

- SENSITIVITY: 80 nanoCi Cs137 is detected with 95% confidence in 0.4 sec.

- GAS FLOW DETECTORS: LIM-21GFA.

- Sensitivity: 20% of 4Pi Cs137 Betas. Detectors can detect lower energy betas down to .05 MeV.

- Sensitive area: 400 square centimeters per detector.

- Operating Voltage: Typically 1900 V with

P-10 gas or 2800 V (optional) with Propane.

- Window Thickness: 5 mg/cm2 (other thicknesses optional).

- Optional: LIM-21GFAT for enhanced gamma sensitivity.

TA TECHNICAL ASSOCIATES

7051 ETON AVENUE * CANOGA PARK, CA 91303

TELEPHONE (818) 883-7043 * FAX(818) 883-6103

e-mail: tagold@nwc.net www.tech-associates.com

LAUNDRY MONITORING SYSTEM

MODEL # LIM-21GFA

CONVERYOR SPECIFICATIONS:

- Conveyor Speed: Continuously variable,

user controlled. 150 mm/sec typical.

- Useful Width: 24'' (610 mm).

- System Weight: 175 kg plus shielding.

- Converyor System: 2 each converyors.

Belt #1: is 6 ft. long, belt carries clothes under detector.

Belt #2: is 4 ft. long, reversible direction converyor, drops CLEAN clothes to one side and drops CONTAMINATED clothes on the other

side.

- Environmental Conditions:

32°F to 122°F, (0° to 50°C).

10% to 95% relative humidity, non-condensing.

- Power Supply: 100-120 VAC or 220 V 50/60 hz with UPS.

ELECTRONICS CHASSIS:

- Front Panel Controls:

Sigma Multiplier (each channel): 1, 1.4, 2.

N of 8 Alarm Set (each channel): 1, 2, 3, 4, 5, 6, 7, 8.

Sample Time: 50, 100, 200 milliseconds.

Overflow Alarm (for background): 10, 20, 40, 80.

Reset push button.

Alarm Disable.

- Rear Panel Controls: Power on-off

High Voltage Adjust: 0-2000 V for P-10 or Geiger gas.

(0-3000 V for propane optional)

- Front Panel Indicators: Average Background

Display (each channel): Two digits.N of 8 Display (each channel):

one digit. Contamination Alarm LED (each channel): red. No Signal

Alarm LED (each channel): yellow.

- Rear Panel Indicators: Power on/off

lamp: red.

High Voltage Meter, 0-2000 volts, (0-3000V Optional).

- Rear Panel Outputs: Remote Alarm Output

Terminals (each channel plus common bell and lamp) Switched AC outlet.

- Alarms Indicating Contamination: 2000Hz alarm and flashing red beacon.

- Power Requirements: 110 V, 60 Hz, 1 A

(220 V and 50 Hz optional).

- Dimensions: 19"W x 20"D

x 11"H - Electronics Console.

- Weight: 45 lbs

- Electronics Console.

- Shipping Weight: 65 lbs - Electronics

Console.

- ALARM PANEL: Wall mountable, silhouette

with lights indicating location of contamination, plus sonalert and

flashing red light.

- GAS FLOW SYSTEM: Flow meter and micro

metering valve are included. Gas tank and pressure regulators are

normally supplied by user. Timer and solenoid operated valve is available

as an option to further minimize gas usage.

TA TECHNICAL ASSOCIATES

7051 ETON AVENUE * CANOGA PARK, CA 91303

TELEPHONE (818) 883-7043 * FAX(818) 883-6103

e-mail: tagold@nwc.net www.tech-associates.com